The logistics industry is the backbone of global trade that ensures goods move efficiently from one place to another.

However, traditional logistics systems often struggle with delays, high costs, and inefficiencies. That’s why AI in logistics is making a game-changing impact.

Artificial intelligence transforms logistics and transportation by improving efficiency, reducing costs, and optimizing supply chains.

AI-driven supply chain optimization to predictive analytics in logistics, businesses are now using advanced technologies to simplify operations and make smarter decisions.

A real-world example of this transformation is DHL which uses AI for logistics to predict demand and optimize delivery routes.

According to a McKinsey report, companies that adopt AI in supply chain and logistics can reduce logistics costs by up to 15% and improve service levels by 65%.

With the rise of AI logistics solutions, businesses can now achieve faster deliveries, real-time tracking, and better resource management.

In this blog, we tried to explain how AI is the future of logistics and why it’s essential for companies to embrace this revolution.

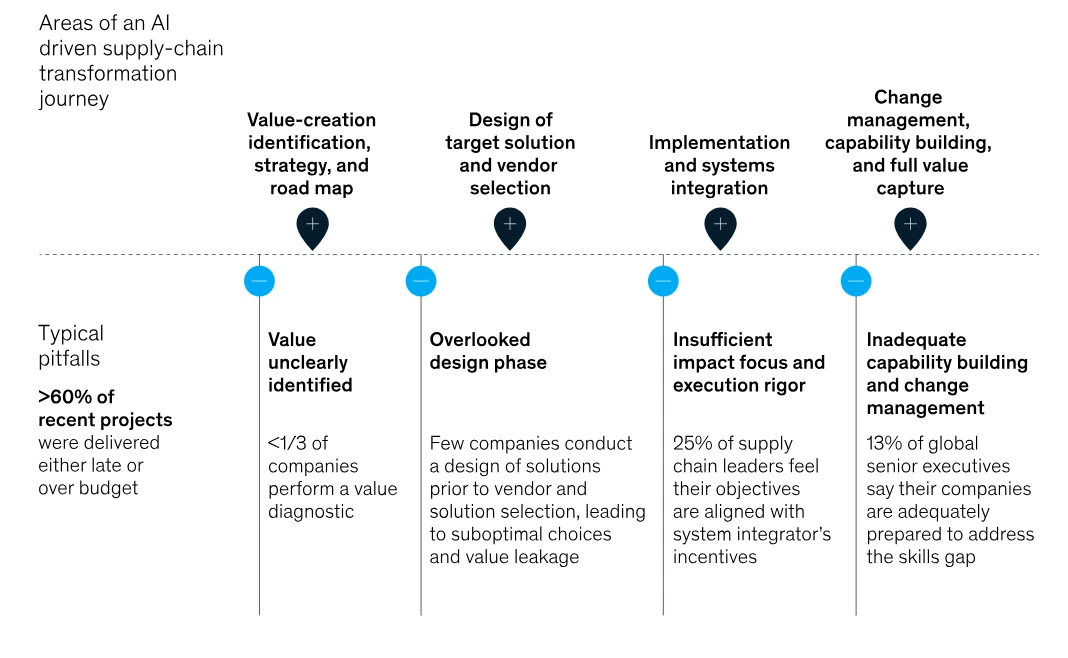

Source: McKinsey

What are the Current Challenges in the Logistics Industry?

The logistics industry faces some major challenges that make it harder for businesses to deliver goods on time and at lower costs.

Traditional logistics systems often face challenges like delays and a lack of real-time data.

Let’s look at some of the biggest problems companies face today.

1. Rising Operational Costs and Inefficiencies

- Running a logistics business isn’t cheap.

- Fuel prices, labor costs, and maintenance expenses keep increasing, making it difficult to maintain profitability.

- Without AI supply chain optimization, businesses often depend upon outdated methods that lead to wasted resources and higher costs.

2. Supply Chain Disruptions and Demand Fluctuations

- Unexpected interruptions like natural disasters, global crises, and sudden changes in consumer demand can cause serious delays.

- AI in supply chain and logistics helps to predict and prepare for such events.

- Companies that depend upon traditional systems struggle to adapt which means delays and inventory shortages.

3. Delays in Freight Management and Warehouse Operations

- Freight management can be difficult.

- Late shipments, poor route planning, and inefficient warehouse management lead to delays and dissatisfied customers.

- AI in freight management can improve delivery schedules and warehouse automation.

- Without it, businesses often face slow operations and increased costs.

4. Limited Visibility and Tracking in Transportation and Logistics

- One of the biggest challenges in logistics is tracking shipments in real time.

- Many companies still lack proper AI for logistics solutions that provide complete visibility.

- This results in lost shipments, delivery errors, and poor customer experience.

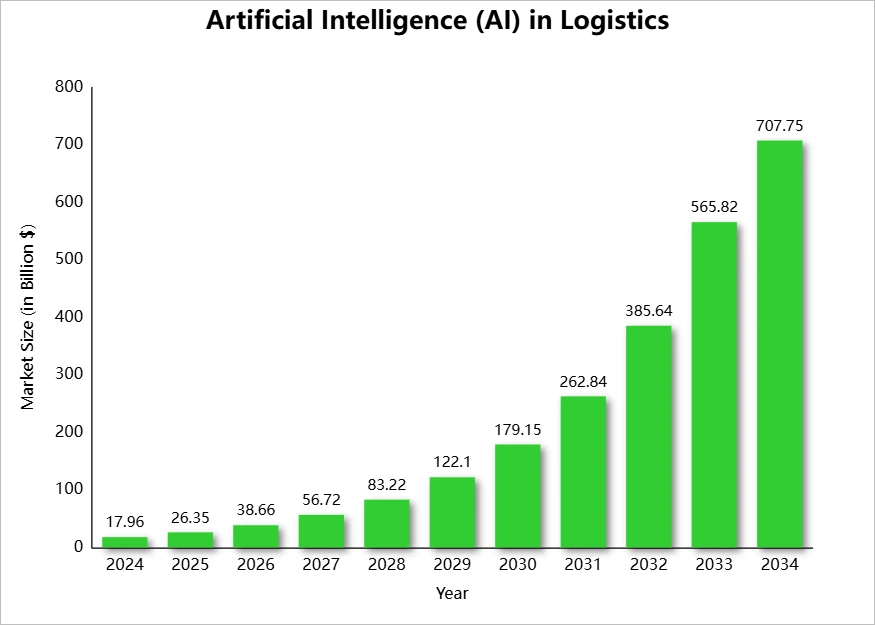

Source: Precedence Research

How AI is the Key for Next-Gen Logistics Solutions?

The logistics industry is going through a major transition with AI-powered logistics solutions.

Businesses are now using artificial intelligence to optimize routes, predict demand, and automate operations.

This shift is helping companies reduce costs, improve efficiency, and minimize risks.

Let’s explore how AI in logistics is changing the game.

1. AI-Powered Logistics Solutions

AI is making logistics smarter, faster, and more reliable.

From warehouse automation to real-time tracking, businesses are using AI-driven tools to improve their supply chain operations.

- Route Optimization: AI analyzes traffic, weather, and delivery schedules to find the fastest and most cost-effective routes.

- Warehouse Automation: AI-powered robots and smart inventory systems help simplify warehouse operations, minimize errors, and improve efficiency.

- AI in Freight Management: AI helps track shipments, optimize truckloads, and prevent delivery delays.

- Smart Inventory Management: AI systems ensure businesses have the right amount of stock at the right time to reduce waste and prevent shortages.

2. Machine Learning in Logistics for Demand Forecasting

One of the biggest challenges in logistics is predicting demand accurately.

Machine learning in logistics helps businesses analyze past trends, customer behavior, and market patterns to forecast future demand.

- Reduces Overstock & Stockouts: AI helps companies maintain just the right inventory levels.

- Optimizes Supply Chain Operations: Predicting demand allows businesses to prepare better and reduce last-minute supply chain disruptions.

- Improves Decision-Making: With AI, companies can make data-driven decisions by improving overall efficiency.

Example: Amazon uses AI-powered demand forecasting to predict how many products customers will buy and when. This allows them to stock their warehouses efficiently and reduce delivery times.

3. AI-Driven Predictive Analytics in Logistics to Mitigate Risks

AI is not just about efficiency but it also helps prevent problems before they happen.

Predictive analytics in logistics uses AI to analyze risks and suggest solutions in advance.

- Identifies Potential Delays: AI can predict shipment delays because of weather, traffic, and supply chain disruptions.

- Prevents Equipment Failures: AI can monitor vehicles and equipment to detect maintenance needs before breakdowns occur.

- Improves Safety: AI-powered monitoring systems help track driver behavior and prevent accidents.

How DHL Uses AI to Improve Logistics?

DHL is one of the world’s largest logistics companies that has successfully integrated AI in supply chain and logistics to improve operations.

- AI-Powered Route Optimization: DHL uses AI to analyze millions of data points and determine the most efficient delivery routes.

- Machine Learning for Demand Forecasting: AI predicts seasonal demand spikes, helping DHL manage inventory more effectively.

- AI-Driven Warehouse Automation: It uses AI-powered robots to speed up package sorting and reduce errors.

The adoption of AI in logistics is no longer optional but it has become a necessity for businesses to stay competitive.

AI for logistics solutions is helping companies reduce costs, improve efficiency, and minimize risks.

How Innovations of AI in Supply Chain and Logistics is the Future?

The supply chain is the backbone of logistics that ensures products reach their destinations smoothly.

Traditional supply chain systems often struggle with inefficiencies, delays, and high operational costs.

AI-driven supply chain optimization is changing that by making logistics smarter, faster, and more reliable.

Here’s how AI in logistics is improving supply chain operations.

1. Smart Route Planning & AI in Freight Management

Efficient transportation is crucial in logistics but delays because of poor route planning, traffic, and unexpected weather conditions can be costly.

AI in freight management is solving this problem by using real-time data to optimize delivery routes and improve efficiency.

How AI Optimizes Delivery Routes to Reduce Costs and Delays?

- AI analyzes historical traffic patterns, delivery schedules, and road conditions to find the best routes.

- Smart routing helps reduce fuel costs, lower delivery times, and improve customer satisfaction.

- AI-powered route optimization reduces idle time to ensure timely deliveries and fewer empty miles.

Real-Time Traffic and Weather Analysis with AI

- AI monitors live traffic updates, road closures, and accidents to reroute deliveries instantly.

- Weather analysis with AI helps logistics companies avoid delays caused by storms, floods, and extreme temperatures.

- AI-based GPS tracking and fleet management systems help businesses maintain on-time deliveries even in unpredictable conditions.

Example: FedEx uses AI logistics solutions to optimize delivery routes to reduce fuel consumption by 10% and reduce delivery times.

2. Warehouse Automation with AI

Traditional warehouses depend upon manual labor for sorting, packing, and managing inventory which means inefficiencies and errors.

AI-based warehouse automation is ensuring the space by making warehouses more autonomous, efficient, and cost-effective.

AI-Driven Robotics and Autonomous Warehouse Systems

- AI-based robots pick, pack, and sort products faster than human workers to reduce operational costs.

- Autonomous forklifts and drones transport goods inside warehouses and improve efficiency.

- AI-driven warehouse management systems (WMS) track inventory levels in real time to reduce human errors.

Predictive Stocking to Reduce Waste and Improve Efficiency

- AI forecasts which products will be in demand based on historical sales data and current trends.

- Prevents overstocking and stock shortages to ensure warehouses maintain the right inventory levels.

- AI-powered warehouse optimization reduces waste, storage costs, and improves order fulfillment speed.

Example: Amazon’s fulfillment centers use AI-driven robots to process orders 20 times faster than traditional warehouses to improve efficiency and reduce shipping costs.

3. AI in Transportation and Fleet Management

Managing a fleet of vehicles efficiently is one of the biggest challenges in logistics.

AI for logistics solutions helps companies to optimize transportation, reduce costs, and make fleets more sustainable.

AI-Powered Logistics Solutions for Autonomous Trucking

- AI is powering self-driving trucks to reduce reliance on human drivers and improve safety.

- Autonomous trucking technology enables long-haul shipments with fewer delays and lower labor costs.

- AI-assisted driving improves fuel efficiency and reduces wear and tear on vehicles.

Optimizing Fuel Consumption and Reducing Environmental Impact

- AI tracks fuel usage and suggests eco-friendly driving techniques to reduce fuel waste.

- Smart route planning cuts down on unnecessary fuel consumption and lowers carbon emissions.

- AI-powered predictive maintenance helps companies prevent breakdowns and extend vehicle lifespans

Example: UPS uses AI-driven fleet optimization to reduce fuel consumption by 10 million gallons per year to make its operations more eco-friendly and cost-efficient.

AI is improving supply chains by making logistics operations faster, smarter, and more cost-effective.

From route optimization and warehouse automation to autonomous trucking and fleet management businesses can take advantage of AI in logistics.

How We Use AI in Supply Chain and Logistics Solutions?

We specialize in using AI for supply chain and logistics solutions that help businesses to simplify operations, reduce costs, and improve supply chain efficiency.

Our development team has years of expertise in AI, machine learning, and automation that help logistics companies to stay ahead in an increasingly competitive market.

We worked on an on demand logistics app called CountMee.

In this app, we integrated features like same-day delivery tracking, a multi-point delivery system, and route optimization to make it one-of-its-kind.

- Custom AI Development: We design customized AI solutions for logistics including predictive analytics, smart route optimization, and AI-powered warehouse automation.

- Smooth System Integration: Our AI solutions easily integrate with existing ERP, fleet management, and inventory control systems for quick digital transformation.

- AI-Powered Demand Forecasting: We use machine learning algorithms to help businesses predict demand, prevent stockouts, and optimize inventory management.

- Advanced Real-Time Tracking: Our AI-based tracking systems improve visibility in supply chain and logistics for efficient fleet and freight management.

- Sustainable AI Solutions: We help companies implement AI-driven sustainability initiatives like route optimization for reduced fuel consumption and smart warehouse management for energy efficiency.

What are the Benefits of AI Logistics and Supply Chain Management?

The logistics industry is going through a fast revolution and AI is at the heart of this transformation.

Businesses that adopt AI in logistics and supply chain management get a competitive advantage by improving efficiency, reducing costs, and making smarter decisions.

Here are some of the biggest benefits of AI-powered logistics solutions and how they impact the industry.

1. Better Efficiency and Cost Reduction

One of the most significant advantages of AI for logistics is its ability to simplify operations and reduce costs.

AI helps companies eliminate inefficiencies, optimize processes, and cut unnecessary expenses.

- AI-driven supply chain optimization helps businesses reduce logistics costs by up to 15% through better planning and resource management.

- Automated warehouses with AI speed up order processing, reduce errors and minimize labor costs.

- AI-powered predictive maintenance helps logistics companies prevent vehicle breakdowns and save money on unexpected repairs.

- Smart route planning reduces fuel consumption and idle time which means lower operational costs.

Example: DHL uses AI for logistics solutions to optimize routes and warehouse operations to save millions in operational costs annually.

2. Improved Real-Time Tracking and Transparency

AI is influencing real-time tracking in logistics by providing businesses and customers with greater visibility into supply chain operations.

- AI-powered tracking systems offer real-time updates on shipments to reduce the chances of lost and delayed deliveries.

- Blockchain and AI in supply chain management improve transparency by making it easier to track goods from production to delivery.

- AI-driven fleet management systems monitor vehicle locations, driver performance, and cargo conditions in real-time.

- Automated notifications and alerts help businesses and customers stay informed about delivery status and potential delays.

Example: FedEx uses AI and IoT sensors to track packages in real time by ensuring that customers get accurate delivery timings.

3. Faster and Smarter Decision-Making

AI allows data-driven decision-making by analyzing vast amounts of data and providing actionable insights.

Logistics companies can make faster, smarter, and more strategic choices.

- AI-powered demand forecasting helps businesses predict future sales trends and adjust inventory accordingly.

- Predictive analytics in logistics identifies potential risks before they occur so that companies can take preventive measures.

- AI-driven automation reduces the dependency upon manual decision-making for fewer errors and improved accuracy.

- Machine learning in logistics continuously improves processes by learning from past data and optimizing operations.

Example: Amazon uses AI-based forecasting models to predict customer demand to stock warehouses efficiently and reduce delivery times.

4. Sustainability and Reduced Carbon Footprint

Sustainability is becoming a priority in logistics, and AI is playing a key role in reducing the industry’s environmental impact.

AI helps companies adopt eco-friendly practices while improving efficiency.

- AI-optimized route planning reduces fuel consumption and lowers carbon emissions.

- Smart warehouses minimize energy waste by automating lighting, heating, and cooling systems.

- AI-driven fleet management ensures vehicles operate at peak efficiency and reduce fuel wastage.

- Predictive maintenance helps keep vehicles in top condition to prevent excessive emissions from poorly maintained engines.

Example: UPS’s AI-powered route optimization system ORION, has helped the company save 10 million gallons of fuel annually to reduce its carbon footprint.

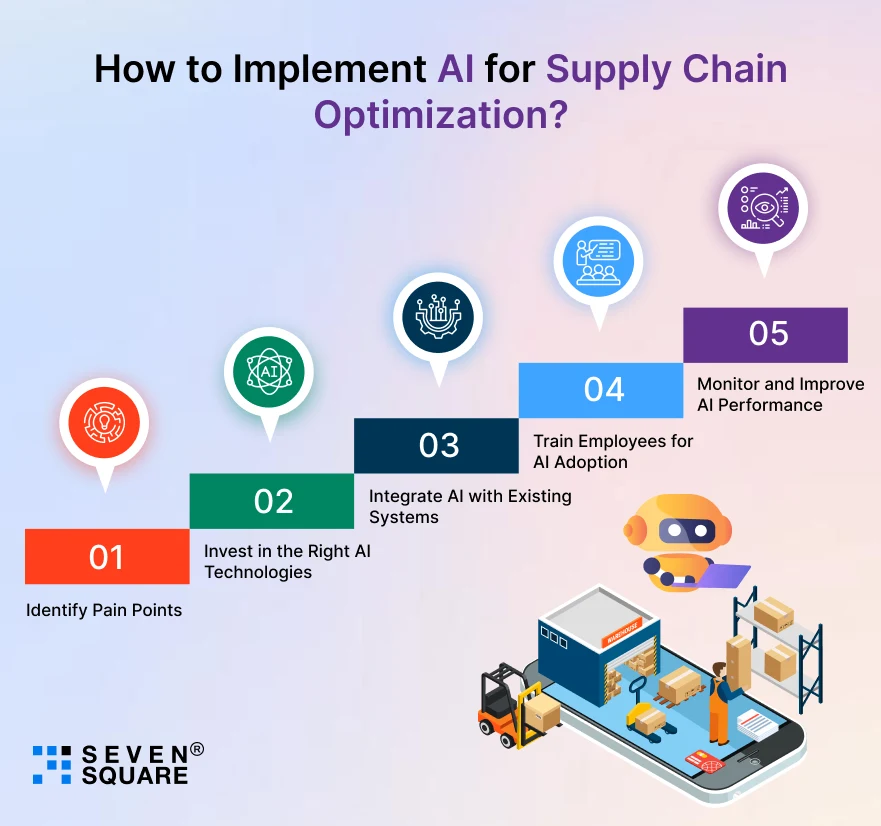

How to Implement AI for Supply Chain Optimization?

The future of logistics is in AI in supply chain and logistics but implementing AI solutions requires careful planning.

Here’s how companies can integrate AI for supply chain optimization, and the challenges they might face while adopting AI in logistics.

Steps to Integrate AI-Driven Logistics Solutions

Adopting AI in logistics and supply chain management requires a structured approach. Businesses need to follow these key steps:

1. Identify Pain Points

- Understand current supply chain challenges like delays, high costs, and inefficiencies.

- Define specific goals for AI adoption like better demand forecasting and automated warehouse management.

2. Invest in the Right AI Technologies

- Use AI-based logistics solutions like predictive analytics, machine learning, and IoT-powered tracking systems.

- Implement AI-driven route optimization for faster and more efficient deliveries.

3. Integrate AI with Existing Systems

- Ensure AI tools work smoothly with current logistics software, ERP systems, and tracking tools.

- Use cloud-based AI solutions for better scalability and flexibility.

4. Train Employees for AI Adoption

- Provide training on how to use AI for logistics solutions effectively.

- Promote a data-driven culture where employees embrace AI insights in decision-making.

5. Monitor and Improve AI Performance

- Continuously analyze AI-driven insights to fine-tune logistics operations.

- Use feedback loops to optimize AI algorithms for better results over time.

Example:Walmart implemented AI-powered demand forecasting and warehouse automation to reduce stock shortages and improve inventory management by 20%.

Challenges in Adopting AI and How to Overcome Them

AI has many benefits but businesses often face certain challenges while integrating AI into their supply chain. Here’s how to overcome these challenges:

1. High Initial Investment

- AI implementation requires upfront costs for software, hardware, and training.

- Solution: Start with small-scale AI adoption and scale up based on results.

2. Data Quality and Integration Issues

- AI needs high-quality and real-time data for accurate predictions.

- Solution: Invest in data management systems to ensure smooth integration with AI platforms.

3. Resistance to Change

- Employees may hesitate to use AI-driven solutions.

- Solution: Conduct training programs and show how AI improves workflows.

4. Cybersecurity Risks

- AI systems depend upon huge amounts of data which makes them vulnerable to cyber threats.

- Solution: Implement strong cybersecurity measures including encrypted data storage and multi-layer authentication.

Example: Maersk is one of the largest shipping companies that faced cybersecurity challenges in AI adoption but overcame them with advanced security protocols and AI-driven fraud detection systems.

FAQs

- AI is affecting logistics by optimizing routes, automating warehouses, improving demand forecasting, and real-time tracking.

- It helps reduce costs, minimize delays, and improve overall supply chain efficiency.

- AI uses machine learning algorithms to analyze historical data, market trends, and customer behavior to predict future demand patterns.

- This helps businesses to optimize inventory, prevent stockouts, and improve supply chain efficiency.

- Yes, AI-based warehouse automation uses robotics, predictive stocking, and computer vision to improve inventory tracking, speed up order fulfillment, and reduce errors.

- AI-powered automated storage and retrieval systems (AS/RS) improve warehouse efficiency.

- AI in route optimization considers factors like traffic, weather, fuel efficiency, and delivery schedules to create the most effective routes

- This helps reduce delays and improve customer satisfaction.

- Yes, SMBs can use AI in logistics solutions for:

- Cost-effective route optimization to save on transportation expenses.

- AI-based inventory management to prevent overstocking or stockouts.

- Automated customer support for better service and engagement.

- Even with limited budgets, SMBs can implement AI incrementally to improve operations.